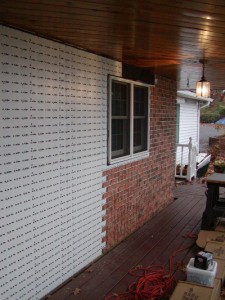

Ambrico’s EZ-Wall system is a Metal Panel Engineered system used to quickly and securely install brick veneer to a variety of sub-straights (metal, frame, masonry), for both interior and exterior applications. Check out our full featured Advanced Thin Brick Calculator for project estimates. The benefits of using the EZ-Wall panel include:

Ambrico’s EZ-Wall system is a Metal Panel Engineered system used to quickly and securely install brick veneer to a variety of sub-straights (metal, frame, masonry), for both interior and exterior applications. Check out our full featured Advanced Thin Brick Calculator for project estimates. The benefits of using the EZ-Wall panel include:

- EZ-Wall panels provide perfect bed joints

- EZ-Wall panels provide a drainage plan

- EZ-Wall panels provide metal “brick ties”

- EZ-Wall panels are constructed of Galvanized steel

- Bricks installed on EZ-Wall panels are less prone to crack

- The Tensile strength of the EZ-Wall steel will carry

- Sidewall wind loading

- High fastener pull-through strength

- Minimize wall racking

The key advantages to using Ambrico’s Engineered Thin Brick Wall system:

- Technological Leadership

- Design Flexibility

- Structural Flexibility

- Installation Speed

- Construction Compatibility

- Positive Mechanical Attachment

- Year Round Installation

- Durability

- Compatibility with LEED Buildings

EZ-Wall Panels:

- Are Field Assembled

- Available in 2’x4′ and 4’X4′ Sizes

- Are 28G, g90 Embossed, Painted Steel

- Lightweight, 7 lbs. per square foot

- Have patented lintel tab patterns for perfect head and bed joints

- Flexible attachment points

- Built in weep system on both sides

- Excellent impact resistance

- Meet rigid fire code requirements

Performance Testing (download (PDF))

- ASTM #-84-89a – Surface Burning Test – Determine the combustibility of the EZ-Wall assembled system

- Flame spread index =0

- Smoke developed index =0

- EZ-Wall offers a Class 1 non-combustible wall cladding

- ASTM E-119-88 – Fire Resistance Test – Determine the fire resistance of EZ-Wall for fire penetration, 2 hour rating

- Temperature did not rise above prescribed levels and water hose test was met

- Certified and listed fire endurance rating of 2 hours was given by a code approved testing

- ASTM-E-72-80 – Windload Structural Testing – Determine wind load capacity of a composite EZ-WALL section based upon stud or girt spacing and deflection design of substrate.

- Transverse Load Test with approved minimum sheathing of 7 mm (1/4”) Extruded foam board.

- Allowable panel load based on a deflection limit of:

L/180 =24/180 = 3.4 mm (.1333 in.) Allowable load = 754 kg/m2 (154.5 PSF) - Allowable panel load based on a deflection limit of: L/240 = 24/240 = 2.5 mm (.1000 in.) Allowable load = 603 kg/m2 (123.6 PSF)

- Allowable panel load based on a deflection limit of:

L/360 = 24/360 = 1.7 mm (.067 in.) Allowable load = 416 kg/m2 (85.3 PSF) - EZ-WALL systems offers minimal restrictions with minimum thickness sheathing, While higher wind resistive sheathing materials will offer maximum height usage.

- ASTM-E-695-85 – Impact Loading – Determine if wall system with EZ-WALL can withstand maximum measured impacts between studs using an impact of a 27 kg (60 lb.) bag.

- No visible cracking of thin brick or mortar.

- EZ-WALL system provides a resistive finish for everyday environment.

- ASTM E-331 – Wind-Driven Rain and Water Penetration – Determine if EZ-WALL system offers a water resistant cladding per ICBO criteria, June, 1990.

- No moisture was observed behind sheathing.

- EZ-WALL system provides a water resistant finish.

- ICBO – Freeze/Thaw Stability of System Test – Determine if EZ-WALL system can withstand thermal cycling.

- No surface changes, deleterious surface effects, delamination of thin veneer or mortar shrinkage when viewed under 5X magnification.

- EZ-WALL system can be used in severe thermal cycling weather conditions.

- ASTM C-1088-88 – Thin Veneer Brick Test – Test and measure physical properties of thin brick veneer (freeze/thaw, type, grade, size and tolerance).

- Approved thin brick passes exterior grade requirements, meets size and tolerance ranges, passes 50 cycles of freezing and thawing, and classifies as either TBS, TBX, TBA (standard, select or architectural).

- Thin veneer can be used and specified in almost any application.

- ANSI A 137.1 -1988 – American National Standard Specification for Ceramic Tile – Test and measure physical properties of ceramic tile.

- Approved tile passes requirements for quarry or paver tile, glazed or unglazed, vitreous or semi-vitreous for application.

- Tile can be used and specified in most EZ-WALL applications.

- ASTM C-446 – Panel (Structural, Physical Qualities, Chemical, Mechanical Stress Tes, Coating Bend Test) – Test and measure structural qualities of panel.

- Panel passes chemical, stress, coating bend, and mechanical requirements with a yield higher than 2320 kg/cm2 (33,000 PSI) and tensile strength over 3160 kg/cm2 (45,000 PSI).

- Panel is produced from structural quality steel.

- ASTM A-525 – Panel (Requirements for Hot-Dip, Zinc-Coated Steel Sheet) – Test and measure zinc coating requirements.

- Panel passes testing and coating requirements for a minimum spangle G-90 classification.

- Panel’s corrosion resistant classification is suitable for commercial application.

- ASTM B-117-90 – Salt Spray (Fog) Testing (For Corrosion) – Evaluate the corrosion resistance of the painted EZ-WALL support panel with manufactured and hand sheared edges when exposed to outside conditions.

- No visible red rust after 3,000 hours of continuous exposure.

- The commercial grade zinc coating does provide sacrificial protection on the cut edges and substantiates the specification and use of the panel in commercial and industrial applications